| Line | Component | Method Used | Priority |

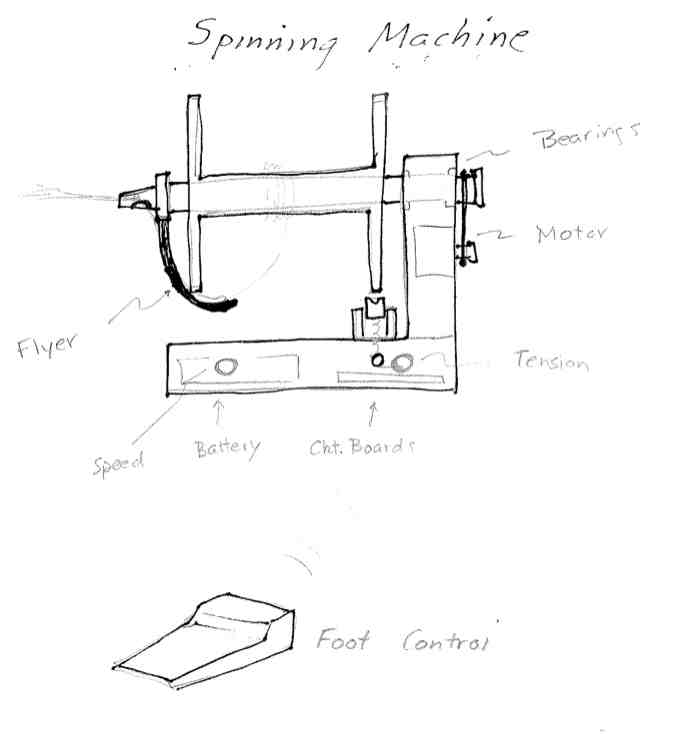

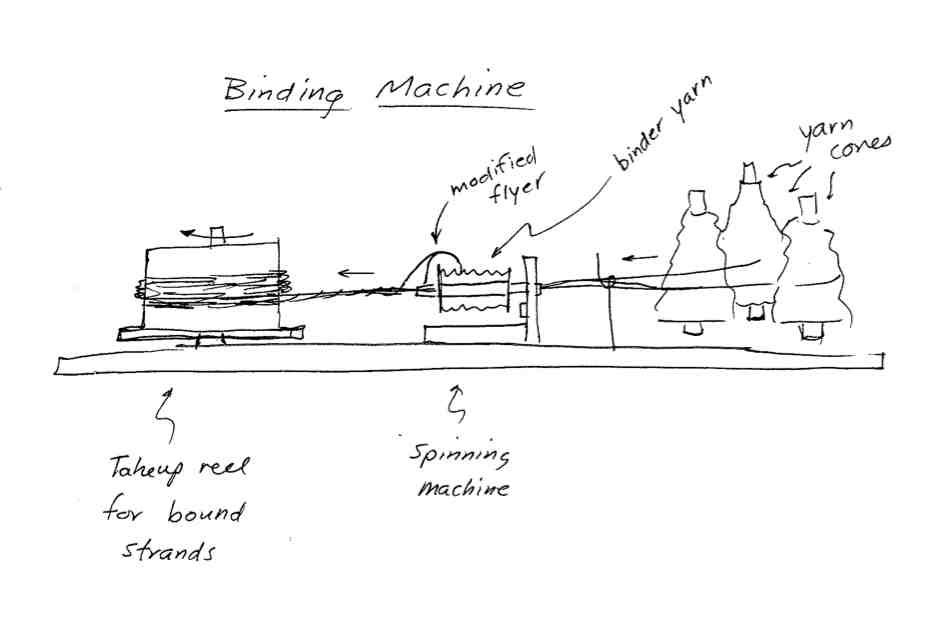

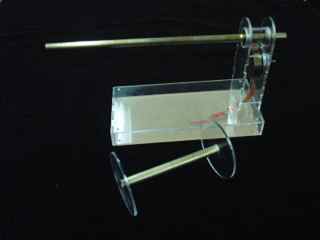

| 1 | Parts of machine and spindles. | 2D cutting, mechanical design |

1 |

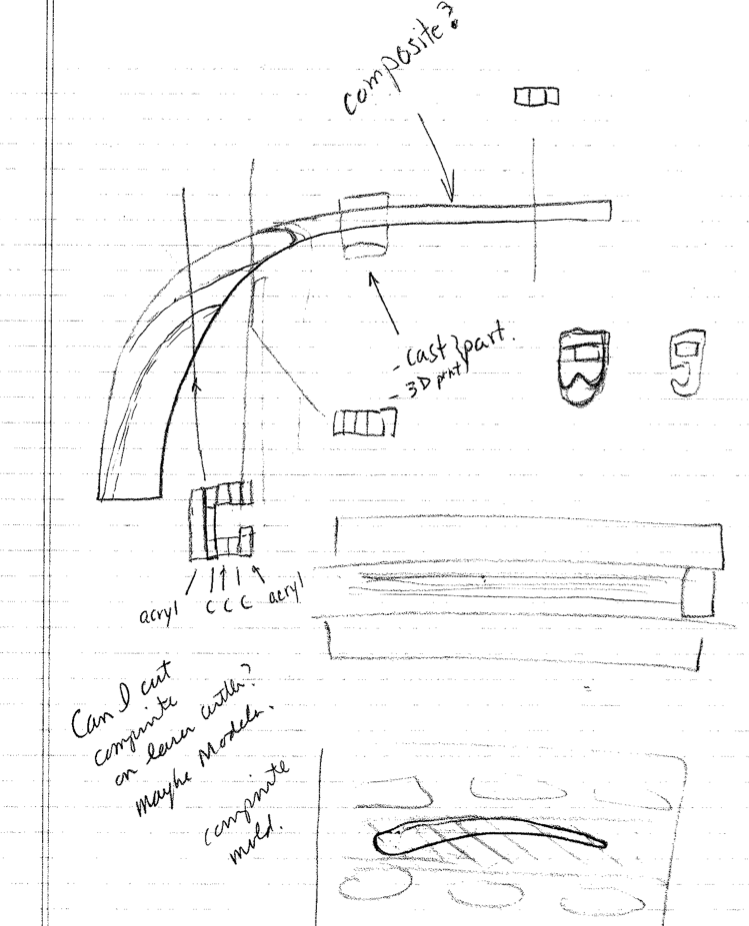

| 2 | Flyer | 3D printing, Casting | 1 |

| Motor. | |||

| 3 | 1. Control brushless DC motor using manufact. board and PWM. or, | Embedded prog, input, output. | 1? |

| 4 | 2. Control brushed DC motor using AVR board, PWM | Embedded prog, input, output. | 1? |

| 5 | 3. Control brushless DC motor using hall sensors with AVR. | Embedded prog, input, output. | 3 |

| 6 | Foot switch. Wireless (acoustic or radio). Turns motor on and off and controls ramp. | Communication | 1 |

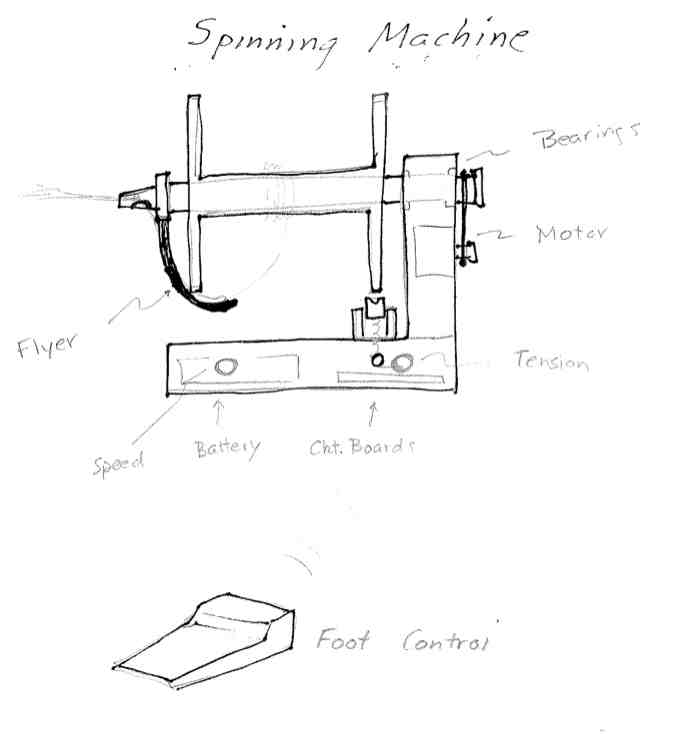

| 7 | Make a binding machine | 2D parts, mechanical design. | 2 |

| 8 | Add a battery (build a charger) | (programming, output devices.) | 2 (3) |

| 9 | Display speed in RPM | Embedded Prog. | 3 |

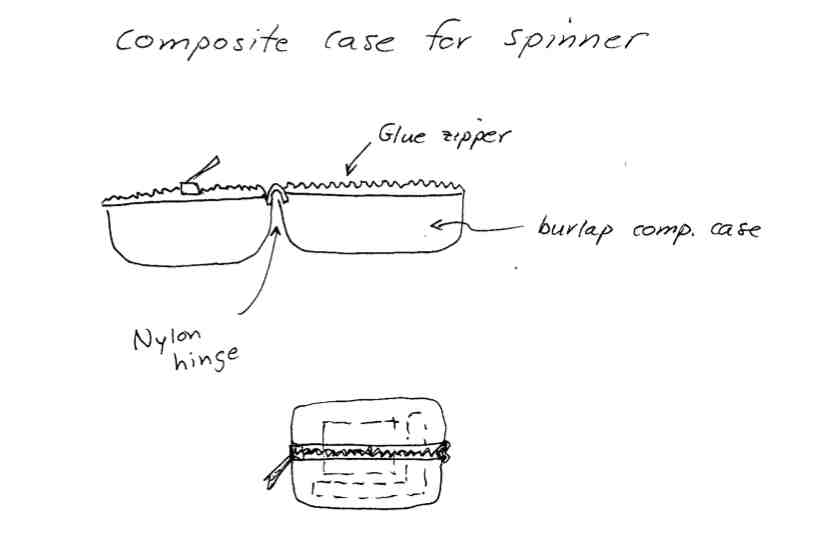

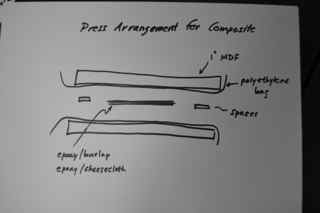

| 10 | Make a composite shell case! | Composites | 3 |

| 11 | Make a computer monitor, or put a sensor together with a computer, to demonstrate data aquisition and display in NumPy, Matlab, Labview...? | Application programming and comm. | 3 |

Notes:

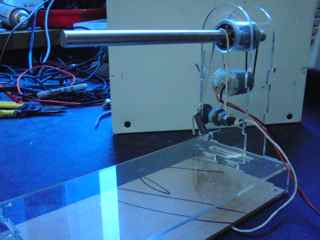

Dec. 2-4. Make acrylic parts and put spinner toghether with motors.

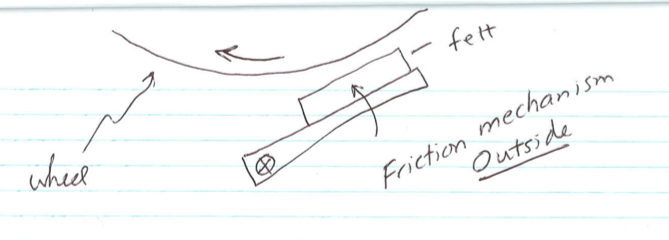

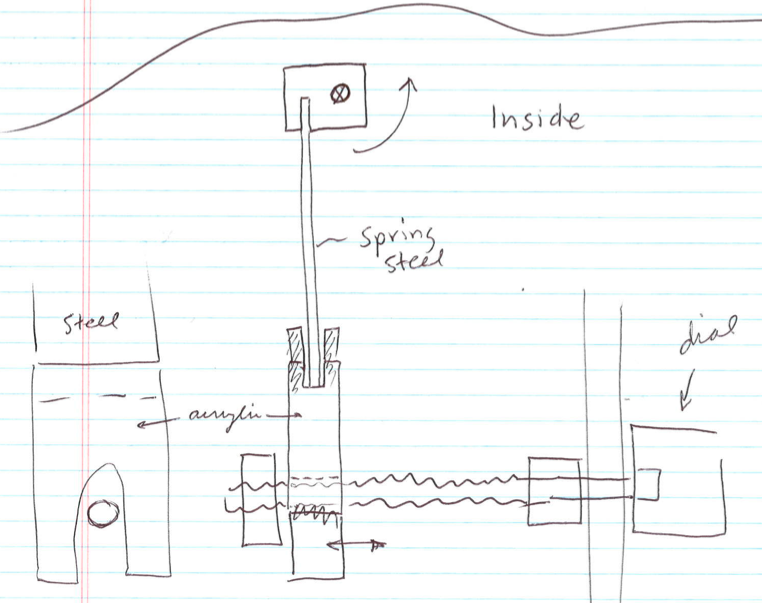

Dec. 5 Design friction mechanism and adjustment

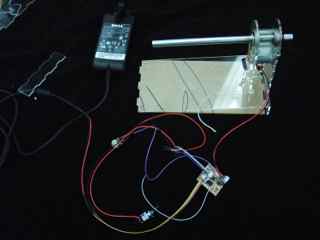

Above I show the 12V brush DC motor from the inventory. Below is an alternate motor - a brushless Hall sensor DC motor. Interesting to compare.

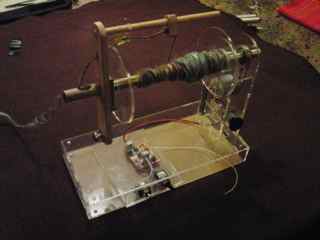

Dec 6-10. Put together a working prototype, using an older flyer.

I may modify this to use on the machine. I do not think it makes sense to cast a version of this. Need to get a better idea of what works first, using a faster turn-around mtehod. I like the idea of a multilayer object.

I may modify this to use on the machine. I do not think it makes sense to cast a version of this. Need to get a better idea of what works first, using a faster turn-around mtehod. I like the idea of a multilayer object.

Program Tiny45 board used in the output devices week to drive the 12V motor from the Fab inventory with programmed PWM at ~ 1kHz.

with much hot glue!

with much hot glue!

| Line | Component | Method Used | Priority |

| 1 | Parts of machine and spindles. | 2D cutting, mechanical design |

0 |

| 2 | Flyer | 3D printing, Composites, 2D cutting. | 1 |

| Motor. | |||

| 3 | 1. Control brushless DC motor using manufact. board and PWM. or, | Embedded prog, input, output. | 4 |

| 4 | 2. Control brushed DC motor using AVR board, PWM | Embedded prog, input, output. | 0 But would be nice to control by speed? I will know more after I use the thing a while. |

| 5 | 3. Control brushless DC motor using hall sensors with AVR Tiny44. | Embedded prog, input, output. | 4 Nice project for January. |

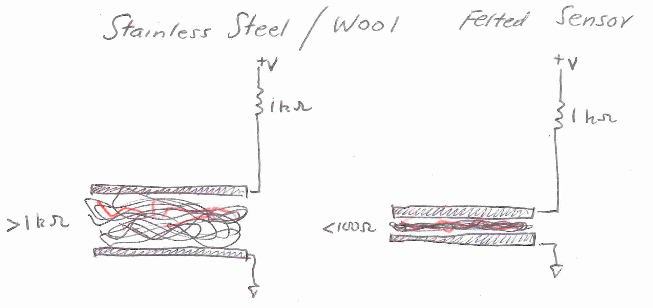

| 6 | Foot switch. Turns motor on and off . Use felted steel sensor. |

Spin and knit up some wool/steel composite yarn. Then felt a swatch of that fabric. | |

| Wireless, using sound or radio chip. | Communication | 2 | |

| Wired, use microcontrollers, but comm using wire rather than wireless. | Sensor, easy communication. | 1 | |

| 7 | Make a binding machine | 2D parts, mechanical design. | 2 I will do this, at least in an improvised way. |

| 8 | Add a battery (build a charger) | (programming, output devices.) | 4 Useful in future versions. |

| 9 | Display speed in RPM | Embedded Prog. output. | 4 |

| 10 | Make a composite shell case! | Composites | 4 Nice idea. |

| 11 | Make a computer monitor, or put a sensor together with a computer, to demonstrate data aquisition and display in NumPy, Matlab, Labview...? | Application programming and comm. | 2 |

| 12 | Tutorial

|

1 |